This website uses cookies so that we can offer you the best possible user experience. The cookie information is stored in your browser and performs functions such as recognising you when you return to our website or helping our team to understand which sections of the website you find most interesting and useful.

The MK2 Panel

The MK2 Panel

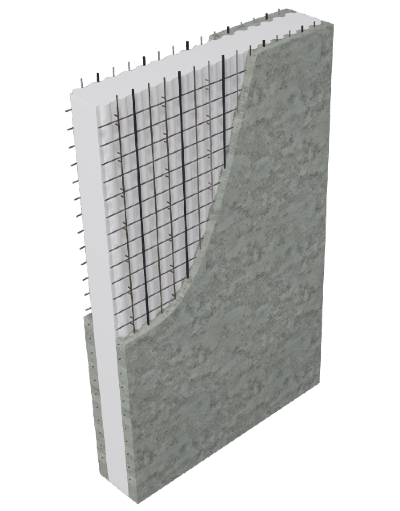

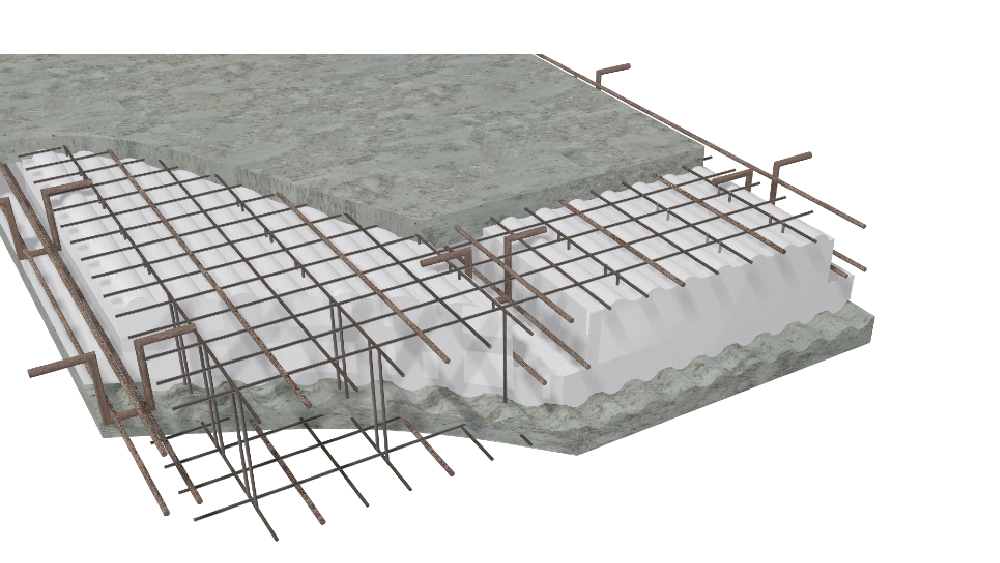

The basic element of the MK2 construction system is the simple MK2 Panel of expanded polystyrene enclosed between two steel meshes linked together by 80 electro-welded connectors per square metre of surface.

The thickness of the expanded polystyrene core can vary from 3 cm to 20 cm, depending on the needs of the architectural project. The minimum density normally used is Class III (5 kg / m3) and Type F (hardly flammable or self-extinguishing).

The meshes are made of high-strength galvanised steel, with an ultimate tension of 700 MPa and are made up of bars with a diameter of 2.50 mm with an average separation of 7.28 by 6.50 cm in the secondary direction, these constituting a basic reinforcement which is completed with 5 mm diameter longitudinal corrugated bars, in the case of structural panels.

The meshes protrude 50 mm on opposite faces, in such a way that when overlapping each other, they ensure continuity by juxtaposition of the reinforcements, without the need to place additional joining elements. For the joins between panels, on the sides where there is no such overlap, continuity is resolved by means of the flat and angular meshes supplied for this purpose, always ensuring the continuity of the reinforcement and EPS in all joints, meeting the requirements of the applicable regulations.

Would you like more information about our Construction Solution?

Traceability

Verification

Monitoring

In our industrialised process there is no margin for error and manufacturing is as important as the construction process

System base

The MK2 Basic Panel

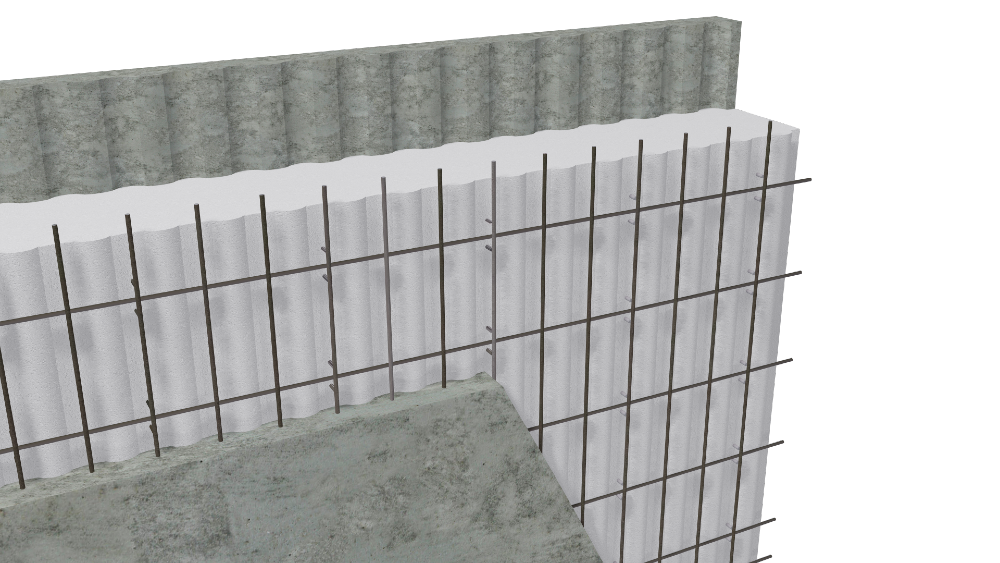

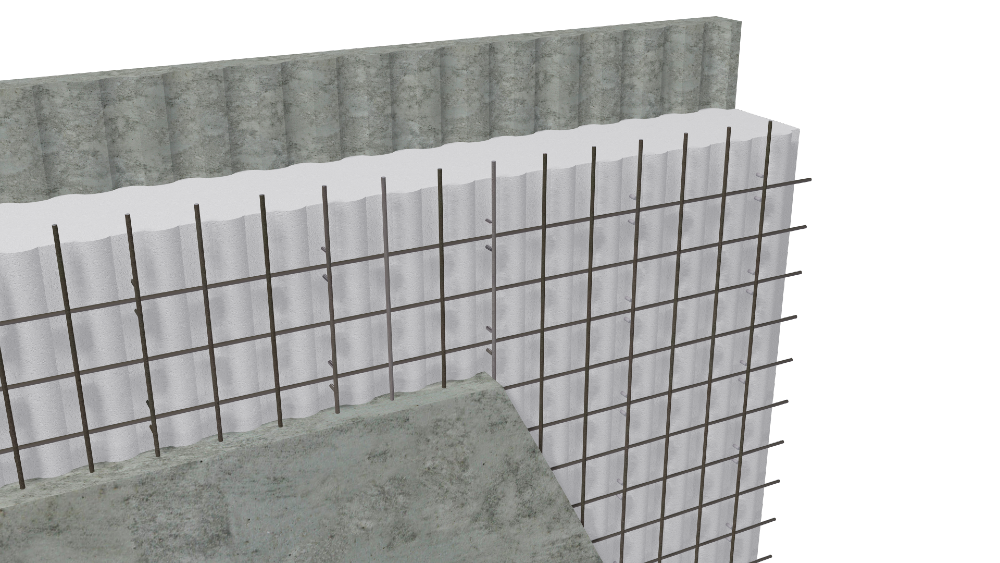

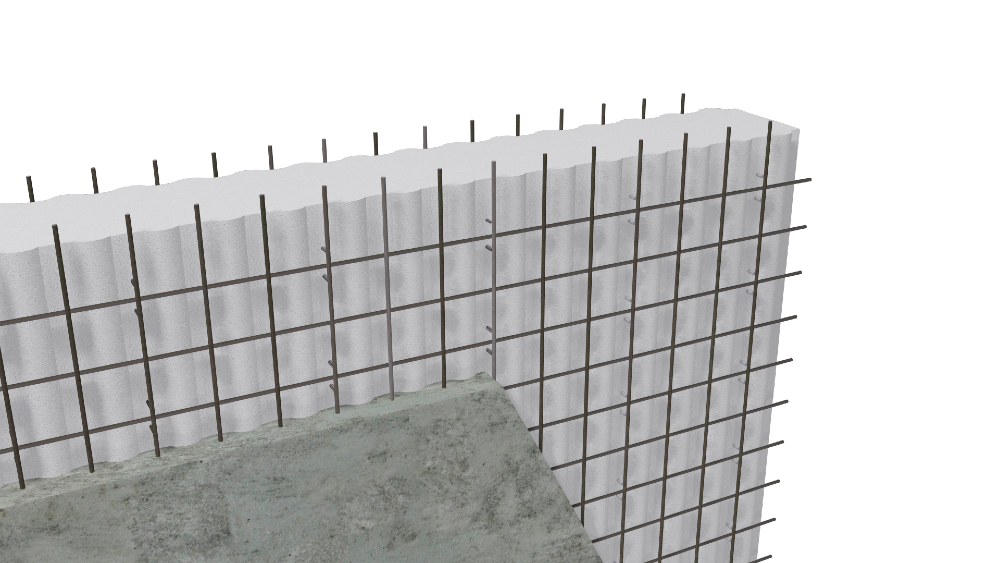

The system base is the MK2 Basic Panel, which consists of an expanded polystyrene core, enclosed between two galvanised steel meshes joined together by connectors, also made of galvanised steel, which is completed on site with two layers of sprayed micro-concrete.

It enables a solution for enclosures, insulation and the supporting structure (up to 6 levels) for all types of buildings.

The different configurations of the MK2 Basic Panel, give rise to five types of panels.

Types of panels

PC Panel

This is a non-structural panel consisting of an expanded polystyrene core (1.125 m wide and 15 kg / m3 density) and two galvanised steel meshes. The meshes are made up of 20 longitudinal bars of Ф 2.4 mm and a cross bar every 130 mm, one on each side of the panel, and joined together by 40 connectors every m2, also made of Ф 3.0 mm galvanised steel. The completion will be done with a layer of micro-concrete, on each of its faces, 3.5 cm thick.

Its use is recommended for divisions and facades in buildings where a traditional work structure already exists.

PN Panel

Non-structural panel consisting of an expanded polystyrene core (1.125 m wide and 15 kg / m3 density) and two galvanised steel meshes. The meshes are made up of 20 longitudinal bars of Ф 2.4 mm and a transversal one every 65 mm (one on each side of the panel). The bars are connected to each other by 80 connectors every m2, also in galvanised steel, Ф 3.0 mm. It will be finished with a layer of micro-concrete, on each of its faces, 3.5 cm thick.

Its use is recommended for divisions and facades in buildings where there is already a structure made up of structural type PR panels.

PR Panel

Structural panel with an expanded polystyrene core (1.125 m wide and 15 kg / m3 density) and two galvanised steel meshes, consisting of 14 longitudinal bars of Ф 2.4 mm + 6 longitudinal bars of Ф 5.0 mm and one cross each 65 mm (one on each side of the panel), joined together by 80 connectors / m2, also in galvanised steel and Ф 3.0 mm. Use as a wall: it will have a layer of micro-concrete, on all its faces, 3.5 cm thick. Use as a slab: on its upper face, it will have a compression layer of 5.5 cm thick micro-concrete.

Suitable to constitute the complete structure of any building (closings, divisions and floors).

PT Panel

Panel based on the same steel mesh as the PN panel, but with a polystyrene core with a more pronounced wave. This allows it to achieve high levels of stiffness with the mortar spray on only one side (4.0 cm average thickness).

Its most common use is for piling, pre-existing closings and the formation of cavity walls.

PF Panel

Panel with the same steel mesh as the PR panel but ribs are formed in the polystyrene core that will allow the pouring of concrete and the inclusion of reinforcing bars to constitute joists made on site. This allows the flexural behaviour of the PR panel to be improved, managing to cover larger project spans.

Its most common use is for floors and roofs with large overloads or with spans that exceed 5 m in length.

Mesh

Angled mesh

These are units made of the same steel mesh as that of the PN panel but bent at 90º. They are used for all joints, both vertical and horizontal, between panels that form an angle between them. Thanks to these, the structural continuity of the steel mesh is achieved in all the elements.

Flat mesh

Like the previous ones, these are units made of the same steel mesh as that of the PN panel but, in this case, flat. They are used for joints between panels on the sides where the usual overlap does not exist and to reinforce the corners (thus avoiding excessive stresses) in the case of opening gaps.